bracesport

Legendary member

Today I was lucky enough to be given a Phoenix 1600 to build for my brother in law - fingers crossed I will get to fly it too!

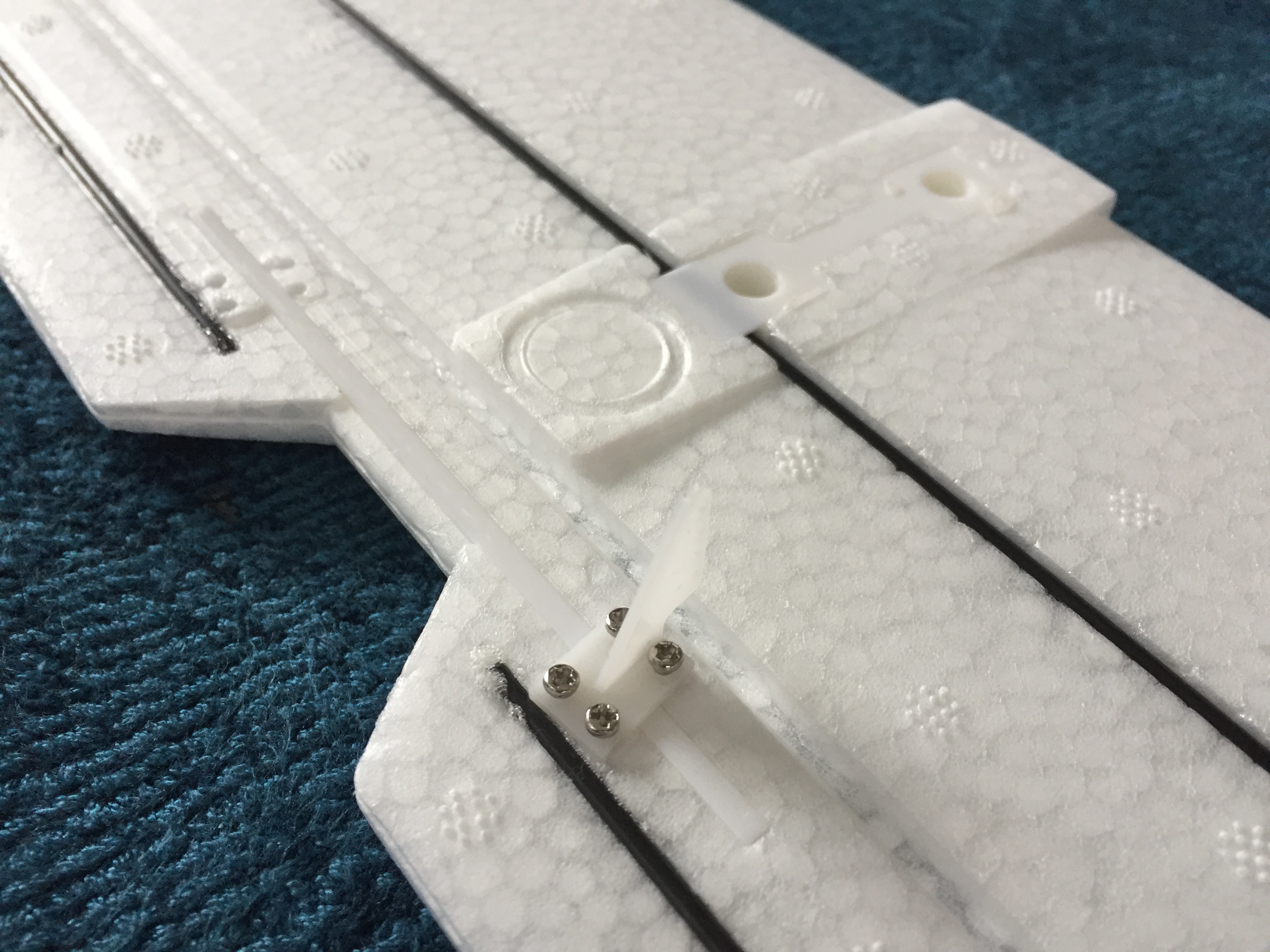

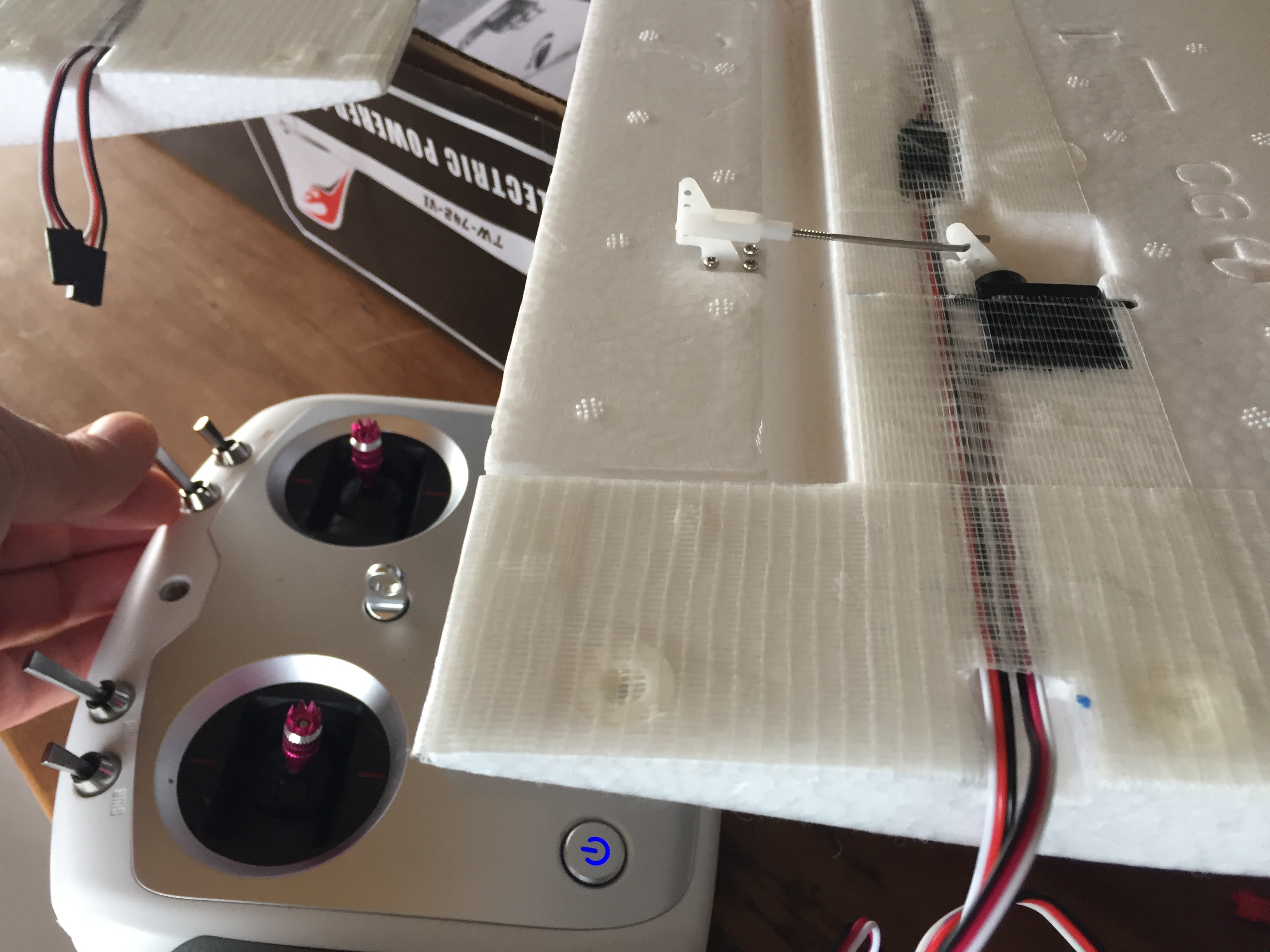

It is an ARF (almost ready to fly) and not surprisingly only has the wing and tail to assemble to the fuse, followed by the control surfaces and linkages.

Never-the-less I thought I would document the process.

It is an ARF (almost ready to fly) and not surprisingly only has the wing and tail to assemble to the fuse, followed by the control surfaces and linkages.

Never-the-less I thought I would document the process.

Last edited: