Destructor

New member

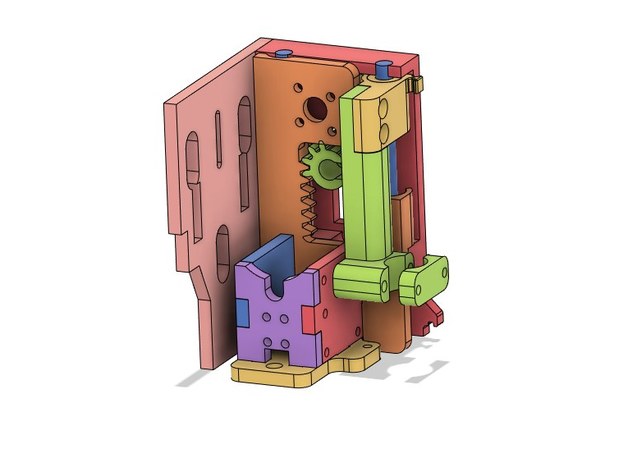

Hey guys. I found the ERC TimSav CNC cutter a few weeks ago and I'm thinking of building it. I had some questions about the machine:

1)Is it worth it to make? If I want to make a foam cutter is this a good, reliable machine?

2) How much space does the CNC cutter take up? How big of a table do I need to keep it?

3)Does it need any surface below it before cutting foam or can it cut foam placed directly on the table or floor?

4)Can it do score cuts?

5)How much printing time do all the parts take? Can I print all the parts on an Ender 3 v2?

6)Is there any way to screw it to the table or floor. I saw in the operation video that the cutter was being taped to the floor; is there a more robust solution?

PS: this is my first post so forgive me if I did anything wrong.

1)Is it worth it to make? If I want to make a foam cutter is this a good, reliable machine?

2) How much space does the CNC cutter take up? How big of a table do I need to keep it?

3)Does it need any surface below it before cutting foam or can it cut foam placed directly on the table or floor?

4)Can it do score cuts?

5)How much printing time do all the parts take? Can I print all the parts on an Ender 3 v2?

6)Is there any way to screw it to the table or floor. I saw in the operation video that the cutter was being taped to the floor; is there a more robust solution?

PS: this is my first post so forgive me if I did anything wrong.