Thanks for the iinfo (Jason, is it?)

Your responses are consistently thorough and helpful.

Jason it is, and thanks

Regarding my question, what are your thoughts about the value of an all-in-one CNC/printer? For the non-professional hobbiest would an all-in-one do an adequate job for a reasonable cost& effort in your opinion? Of all the places to start, where/with what would you recommend?

—Jim

My feeling towards an all in one is...it's ok but not ideal. 3D printers are SLOW. That's their biggest issue IMHO, it takes hours to make a single part. A local friend is building an openBuilds Sphinx CNC:

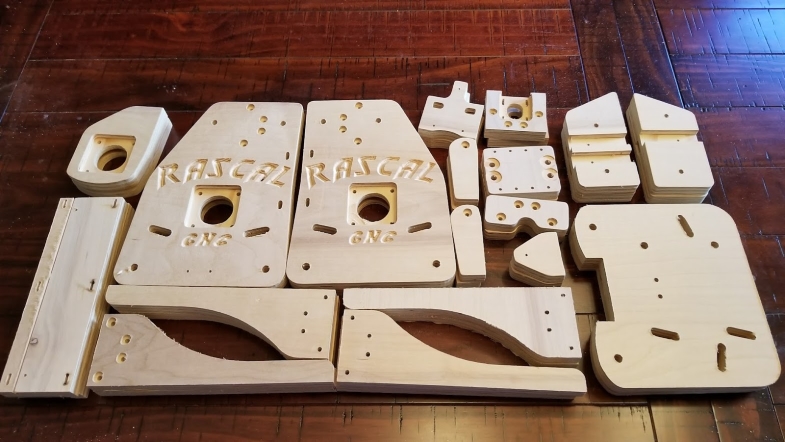

http://openbuilds.org/builds/c-beam-sphinx.3605/ he asked me if I could print the plates for him with my 3D printer since he saw some people had used 3d printed plates to get it up and running. Well...I could. But...the smallest plate was looking like a 2 hour+ print and there are 8 plates. I was able to cut all of the plates in less than an hour on my CNC. I only cut them from MDF - but they're probably still stronger than 3D printed would have been and should be good enough to get him and and going enough to use the machine to cut new plates for itself.

A CNC as a 3D printer is generally probably going to be slower than an already slow 3D printer. CNC's have heavier parts and that means slower accelerations. Most CNC's are capable of faster movement speeds than would be practical for 3D printing - but with 3D printing there's a lot of starting/stopping so acceleration plays a larger roll than it usually does with milling.

So...along those lines while I have an extruder setup to mount on my CNC I haven't because I don't want to tie the machine up for hours on end doing prints. I mostly have it so I can do prints that won't fit on my printer (like the neck of the

Hovalin I'm working on for my wife.)

That said there are quite a few people who built MPCNC's with parts they purchased and then use them as 3D printers more than they use them as CNC's. It's a matter of your needs really.

Personally I'd say if you have room and budget for both then it's best to get both. Of course that's not always the case. And if you have to compromise it's far better to use a CNC as a 3D printer than to try and use a 3D printer as a CNC (printers are much less rigid and smaller.) But adapting most CNC machines to work as 3D printers isn't straight forward and would take a good bit of knowledge about controllers/gcode to get working well.

If you really want an all in one then the MPCNC is a good option since there are quite a few people doing that with it already. The Rascal would also be a good platform for it - but you'd be on your own for controlling an extruder. If I was to try and turn a Rascal into an all in one I'd probably ditch the GRBL board and go with a RAMPS or RAMBO - you'd give up some ease of use for milling but you'd have a much easier time using it as a printer.

But...what I would do is build one machine and then use it to build the other. In fact...that's what I did

I built a 3D printer from a kit (Just under $300 when I did it almost 2 years ago) and then used it to print the parts to build my MPCNC. I use the snot out of my 3D printer...I use the CNC a lot too...but since it's messier, noisier, and stock tends to cost more than filament I don't use it quite as much as the 3D printer.

You could also go the other way. Build a CNC like the Rascal and use it to cut and print parts (or find someone to print parts for you) for a 3D printer.

So...personally I wouldn't want to give up either of my machines or try to make one of them do both jobs. If I absolutely had to though I'd go with just the CNC and set it up for printing. But doing that with a CNC other than the MPCNC would take more work than the MPCNC due to the MPCNC using electronics that are more derived from the 3D printing world than the traditional CNC world.

)

)