You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Rascal CNC

- Thread starter SP0NZ

- Start date

-

- Tags

- cnc diy foam board

Ordered everything. Just waiting for the short kit to become available.

Woo! Glad you will be joining us!

Couple quick questions:

If the IPM is slowed down with the Rascal cut 3/4 furniture grade ply?

What is the other "recommended" materials besides foam?

What program is recommended for making the files to custom things? I have some experience with 3D printing, but this is all new to me and appears to be significantly different than 3D printing as far as software, and file creation. Thanks. Already started ordering parts, and on the "list" for the wooden short kit.

Yes, at a slower rate the Rascal will cut 3/4 furniture ply. Foam (all kinds) and ply would be the main materials we will be using, but I imagine anything as hard or softer than ply would also cut. For all the software stuff we are making a video to cover those details - stay tuned!

Dipped my feet into the pool, now have to keep buying the parts a few at a time until all are bought. My goal is less than a year!

Welcome! This is going to be a fun journey and I love seeing new faces jumping aboard.

Duggem

Live like no one else...

MDF Base

I went to Lowe's this morning to get the MDF base board.

For ~ $25 out the door I was able to get two of them cut from one 49" x 97" sheet so if you go in together with someone, you can reduce the projected cost of this part by at least half.

If you're near me and need a base board, I have an extra one that I'll sell for $10. PM me if interested.

Edit: Keeping my extra for use as waste board.

I went to Lowe's this morning to get the MDF base board.

For ~ $25 out the door I was able to get two of them cut from one 49" x 97" sheet so if you go in together with someone, you can reduce the projected cost of this part by at least half.

Edit: Keeping my extra for use as waste board.

Last edited:

I went to Lowe's this morning to get the MDF base board.

For ~ $25 out the door I was able to get two of them cut from one 49" x 97" sheet so if you go in together with someone, you can reduce the projected cost of this part by at least half.

It's also handy to have extra MDF. It's fairly easy to cut so it's nice to have some on hand for experimenting with. And you may want to use it as a waste board under what you're cutting to protect the bed of your machine.

I actually use particle board as a wasteboard when cutting plastic and wood but MDF would work as well. When cutting foam I like to use foam as a waste board since it's gentler on the needle cutter I prefer over a router/spindle for foam cutting. So if you're only planning on cutting foam that extra MDF may not be as handy. But once you have a CNC you'll probably start finding all kinds of uses for it you didn't anticipate when you built it

jamiesmed34

New member

Hi everyone, I’m new to the forum but have been watching and reading FT content for awhile. I made my first foam board plane this past summer with my son, and it was awesome, and we want to build more. I have been wanting to build a CNC for about 10 years and when I came across the Rascal CNC pod cast I new this was the right one to fuel our airplane fun. I ordered most of the parts and just waiting for them to come and my turn for the wood parts from Kevin. I’m sure I will have many questions along the way but right now I just have one. I’m looking to get a new computer/ laptop for personal uses and want it to run the CNC, what specs should I be looking for? Also is there any video of the Rascal running? I would love to see it cut.

blackkrystal73

Member

The z stepper is a NEMA 17 it has a 5mm output shaft, it hooks to the 8mm threaded rod. You'll need the 5mm to 8mm one.. I'll look at the link when i get home..

Thanks for bringing this to our attention..

- Kevin

Thanks for bringing this to our attention..

- Kevin

blackkrystal73

Member

Hi everyone, I’m new to the forum but have been watching and reading FT content for awhile. I made my first foam board plane this past summer with my son, and it was awesome, and we want to build more. I have been wanting to build a CNC for about 10 years and when I came across the Rascal CNC pod cast I new this was the right one to fuel our airplane fun. I ordered most of the parts and just waiting for them to come and my turn for the wood parts from Kevin. I’m sure I will have many questions along the way but right now I just have one. I’m looking to get a new computer/ laptop for personal uses and want it to run the CNC, what specs should I be looking for? Also is there any video of the Rascal running? I would love to see it cut.

Welcome JamiesMed34.

glad your interested in our project. I should have a batch of parts out this monday, and another batch toward the end of next week. I normally cut 3 kits at a time.

As far as PC specs go.... this is a loaded question.. my advice is do your home work, there are plenty of videos and how to's out there. I build my desktop computers and buy laptops. but as things change it easy for a PC to become out dated quickly.. As far as the running of the CNC it takes near nothing as far as computing power to run a CNC. but programming is a beast. Im using Fusion 360 and my Machine i just built 3 months ago needs more memory, its in the mail...lol

I'd say go as big as you can afford to go. nothing last forever. but you might get 5 years out of it.

-Kevin

Hell2Go

Member

how long is the 8mm lead screw? I saw a nema 17 with a 400mm lead screw for $22.99 with a coupler and bearings on Banggood.com.

https://www.banggood.com/NEMA17-Ste...nd-Shaft-Coupling-p-1118176.html?rmmds=search

https://www.banggood.com/NEMA17-Ste...nd-Shaft-Coupling-p-1118176.html?rmmds=search

Hell2Go

Member

also, have you talked with these guys about a pin cutter head on a cnc machine for cutting DTFB?

http://forum.flitetest.com/showthread.php?24251-Cutting-foam-sheets-with-a-needle!&highlight=nerdnic

http://forum.flitetest.com/showthread.php?24251-Cutting-foam-sheets-with-a-needle!&highlight=nerdnic

Duggem

Live like no one else...

how long is the 8mm lead screw?

250mm

I have a question, how hard would it be to mod the design for a longer bed, to have a cutting area that could cut something about 72 inches long?

I'm not sure if you can get to 72 inches but you can do 1500mm and still use 95% of the Rascal parts.

also, have you talked with these guys about a pin cutter head on a cnc machine for cutting DTFB?

http://forum.flitetest.com/showthread.php?24251-Cutting-foam-sheets-with-a-needle!&highlight=nerdnic

Yeah definitely, the pin cutter is a really cool idea. Our hope is that as more people get their hands on the Rascal we'll start seeing mods and attachments like this. It won't take much at all to modify the Rascal to work as a pin cutter if desired.

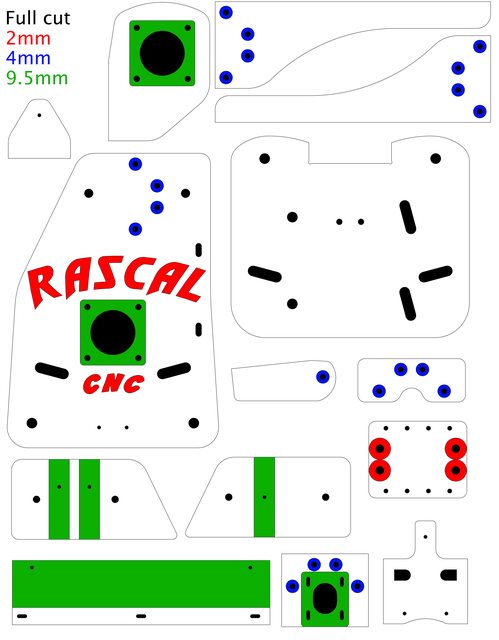

I'd gladly make a modified version of my needle cutter designed to mount to the Rascal. I was just waiting to see some builds first to get a feel for how the tool mounting is accomplished. I've looked at the DXF files, but there doesn't seem to be a lot of info about which piece is which...I can figure most of them out but I can't picture the fully assembled Z in my head yet.

I saw Doug Miller's post on the FB group with his Z coming together - but no tool mounted yet so I'm still not 100% sure how the mounting is achieved.

I can think of a few ways it could be done.

Cutter designed to mount in place of the spindle with the same bolt pattern.

Cutter designed to mount in the spindle mount - loosen the screws, remove the spindle, mount the needle in it's place.

Cutter designed to ride tandem with the spindle (Could run into some clearance issues though.)

Modify the plate the tools mount to to create a quick release setup allowing changing toolheads with minimal or no tools.

Modify the plate to use a needle fulltime instead of a spindle for a slightly cheaper build.

But...as David who introduced us to the needle cutter commented yesterday the needle cutter isn't limited to any one machine or design. It's just a concept that can and has been applied many different ways.

With a Rascal up and running with default spindle you could cut wooden or plastic parts to build a needle cutter out of. Or you could strap a cheap $20 extruder to it and use it as a makeshift 3D printer to print one. Heck, you could even strap a cheap laser on and cut one from thin ply. Tons of options!

I'm more than willing to adjust my cutter design(s) or create a new one for the Rascal - just need some more specifics on your builds and goals to make it happen

I saw Doug Miller's post on the FB group with his Z coming together - but no tool mounted yet so I'm still not 100% sure how the mounting is achieved.

I can think of a few ways it could be done.

Cutter designed to mount in place of the spindle with the same bolt pattern.

Cutter designed to mount in the spindle mount - loosen the screws, remove the spindle, mount the needle in it's place.

Cutter designed to ride tandem with the spindle (Could run into some clearance issues though.)

Modify the plate the tools mount to to create a quick release setup allowing changing toolheads with minimal or no tools.

Modify the plate to use a needle fulltime instead of a spindle for a slightly cheaper build.

But...as David who introduced us to the needle cutter commented yesterday the needle cutter isn't limited to any one machine or design. It's just a concept that can and has been applied many different ways.

With a Rascal up and running with default spindle you could cut wooden or plastic parts to build a needle cutter out of. Or you could strap a cheap $20 extruder to it and use it as a makeshift 3D printer to print one. Heck, you could even strap a cheap laser on and cut one from thin ply. Tons of options!

I'm more than willing to adjust my cutter design(s) or create a new one for the Rascal - just need some more specifics on your builds and goals to make it happen

That fills in a lot of my questions

So it looks like the two easiest ways to swap to a needle cutter would be to either loosen the two clamp bolts and design it to fit in the spindle collar. Or loosen the 8 t-nuts and remove the spindle and plate then mount the needle cutter with t-nuts.

The t-nuts looks potentially more annoying since there are more of them to deal with. But I'm not sure how well those spindle clamps are designed and if loosening/tightening them would be a good idea. That would also make for s trickier design on the needle cutter if it had to mount in the spindle clamp.

Curious what those of you actually building the Rascal think would be the easier approach since you've got hardware in your hands

So it looks like the two easiest ways to swap to a needle cutter would be to either loosen the two clamp bolts and design it to fit in the spindle collar. Or loosen the 8 t-nuts and remove the spindle and plate then mount the needle cutter with t-nuts.

The t-nuts looks potentially more annoying since there are more of them to deal with. But I'm not sure how well those spindle clamps are designed and if loosening/tightening them would be a good idea. That would also make for s trickier design on the needle cutter if it had to mount in the spindle clamp.

Curious what those of you actually building the Rascal think would be the easier approach since you've got hardware in your hands

Similar threads

- Replies

- 6

- Views

- 2K

- Replies

- 54

- Views

- 19K

- Replies

- 3

- Views

- 2K

- Replies

- 4

- Views

- 3K