Andrea

Member

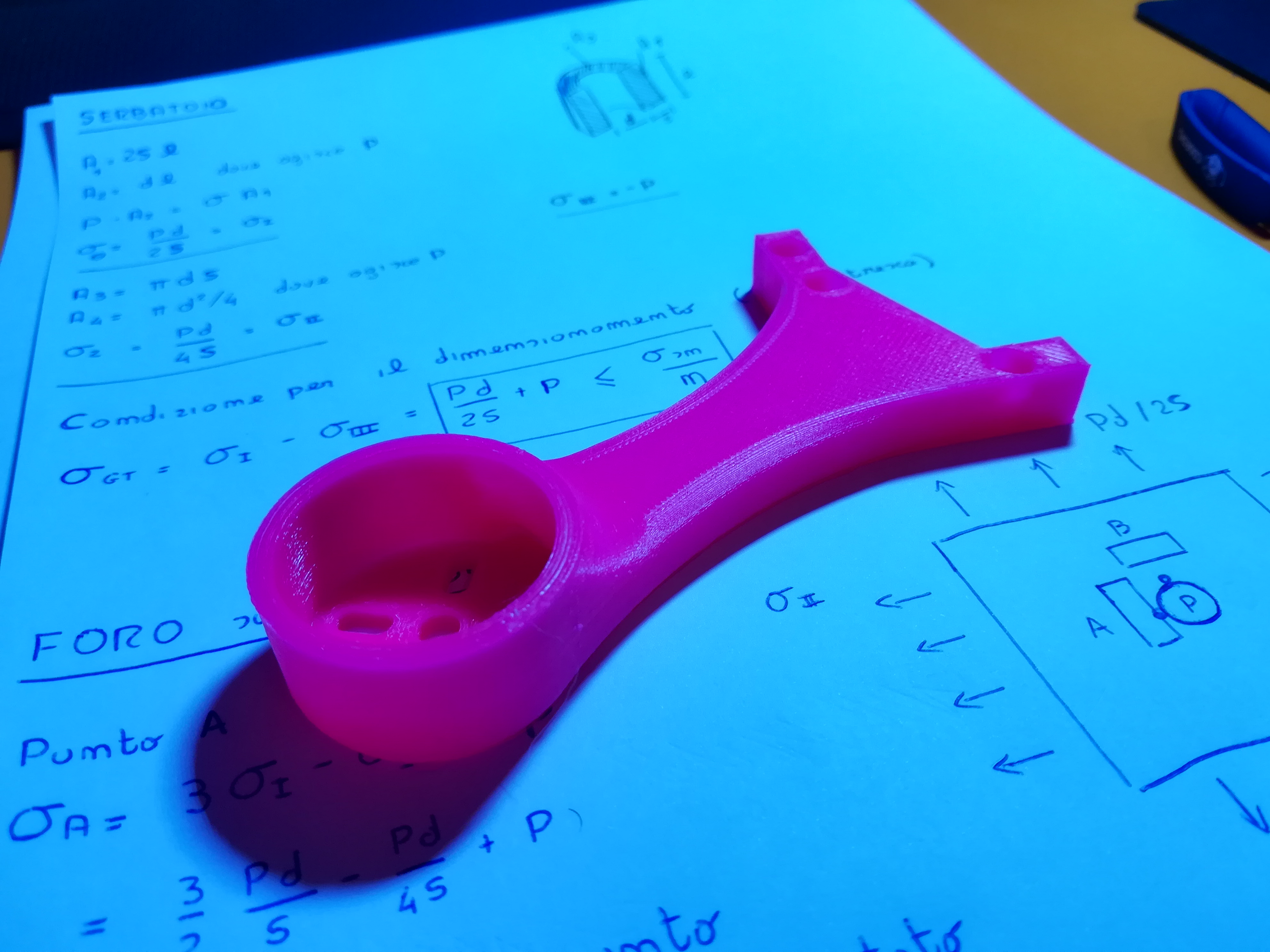

Hi, I'm printing my first quadcopter, I drawn all the stuff and now is under printing process, I choose orange for my first try:

This is the render that i've made:

I 'll keep this post updated as soon i finish to print some parts.

I'm now looking for the Esc because there is not so much room inside it.

This is the render that i've made:

I 'll keep this post updated as soon i finish to print some parts.

I'm now looking for the Esc because there is not so much room inside it.

Last edited: