T2 OpenProjects

New member

Intro (Skip if You Want!):

I've been a long time lurker on these forums, but I do a fair bit of designing/building/flying of planes, and it has been a long term goal for me to embark on a project specifically for by fixed wing fans and put it up on these forums and become a contributor myself. I've concocted the idea of a nice series of 3D printed planes, all of which would be open source, building up from a simple trainer all the way to long range FPV and aerobatics. This, I decided, will be the project (or series of) that gets posted to these forums. The first plane i'll be going for is the trainer; a simple easy to fly, easy to acquire, easy to repair entry level option for those who want to enter the hobby, but are daunted by the prices and complexity of some of the models out there.

The Trainer: OpenFlyer Mk. I:

Ideally, this plane would be no more than 1200 mm in span and 800 mm in length; my metric for cost of the frame is based off the cost of a 1 KG role of PETG filament: ~$40 (AU), $25 (US). My goal for the all up materials cost of printing this aircraft would be about half of the aforementioned numbers; this leaves the electronics as the main cost when building one of these planes...as is the usual.

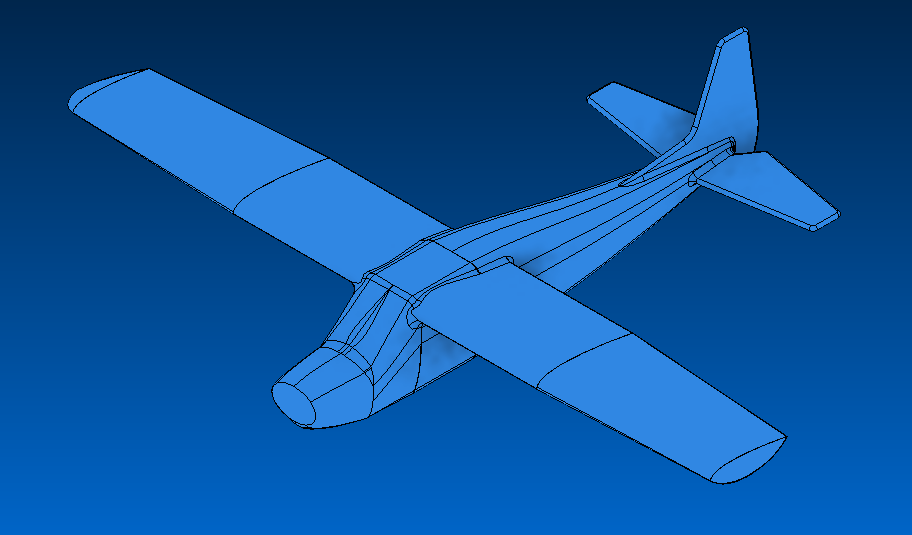

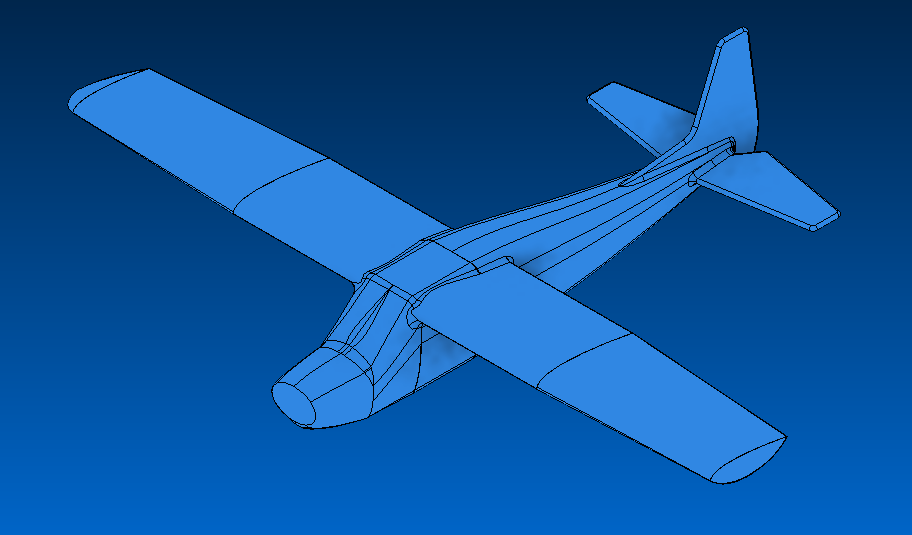

Give those (remarkably basic) constraints, I've developed a very rudimentary sketch of an early model - surprise, it looks very familiar to many other tail daggers (for a reason)

Obviously this model is lacking in quite a few areas. This is just a 10 minute quick collection of my thoughts essentially; this aspect ratio, this chord, angle of incidence, span, sweep, and so on. The model will become much more refined, and will probably end up looking quite different to the one shown above, as it is changed to accommodate predicted loads or inadequacies in various areas of performance.

Desired (Nominal) Specifications:

Wingspan: 1100 mm

Length: 800 mm

Frame Weight: <500 Grams

Electronics Package Weight: <500 Grams

Static Thrust: >800 Grams

Top Speed: 30 m/s

Take Off Speed (clean b/c no flaps): 15 m/s

Cruise Speed: 25 m/s

Peak Engine Revolutions: 14000 RPM

Peak Engine Power: 170 Watts

Peak Engine Voltage: 12

Propeller: APC E 7x5

Flight Time: >30 Minutes

Max Cargo: >150 Grams

A Bit of Info About Me:

Seeing as I haven't contributed in the past, its probably fair I give a bit of background...show that I'm not just making wild guesses with all this

I'm a big fan of FliteTest's foam models, and the simple storch gave me a lot of good memories and experience; it also sent me down the endless path of designing building my own foam models, needless to say the first few didn't work out too great, but I got the hang of it eventually. I've always enjoyed using CAD software, and so it was inevitable that my interest in that would permeate through to my interest in planes...indeed it did! I started out designing a few wooden models that I had laser cut; by this point my experience with making practical designs and sourcing parts was decent enough that these wooden models were fairly reliable and fun to fly.

One of my favourite designs...a 2.5 meter behemoth

While designing these wooden models, I also started a few design projects that were only possible with 3D printing...they were fully fleshed out, servos, motors, control surfaces, all the goods, but they were shelved due to a lack of 3D printing capabilities. Recently though, I got a 3D printer...this has opened up quite a few of these projects again...its good to see them coming back to life . Among the designs coming back to life is a re-mastering of the above aircraft; redesigning it for 3D printing.

. Among the designs coming back to life is a re-mastering of the above aircraft; redesigning it for 3D printing.

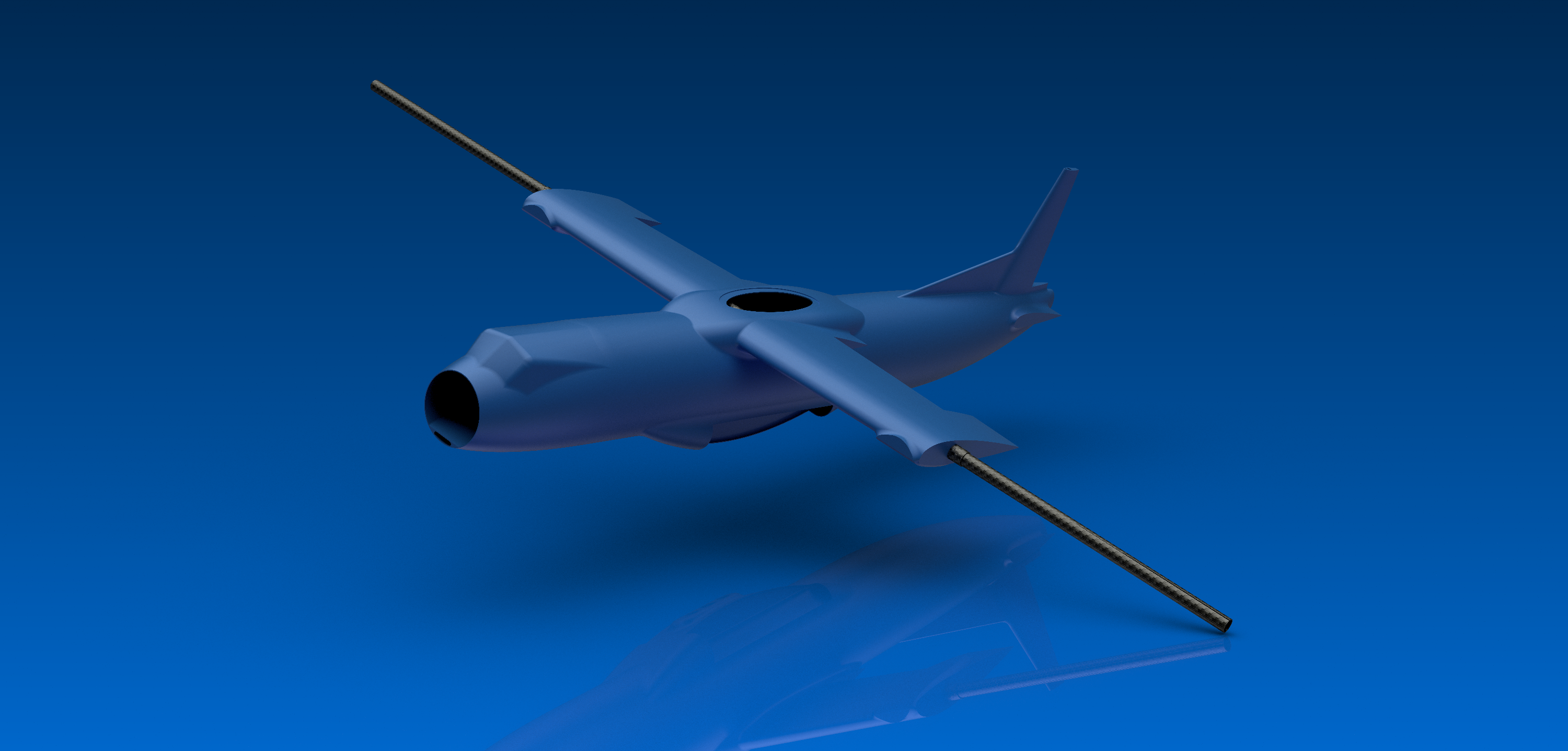

The concept model

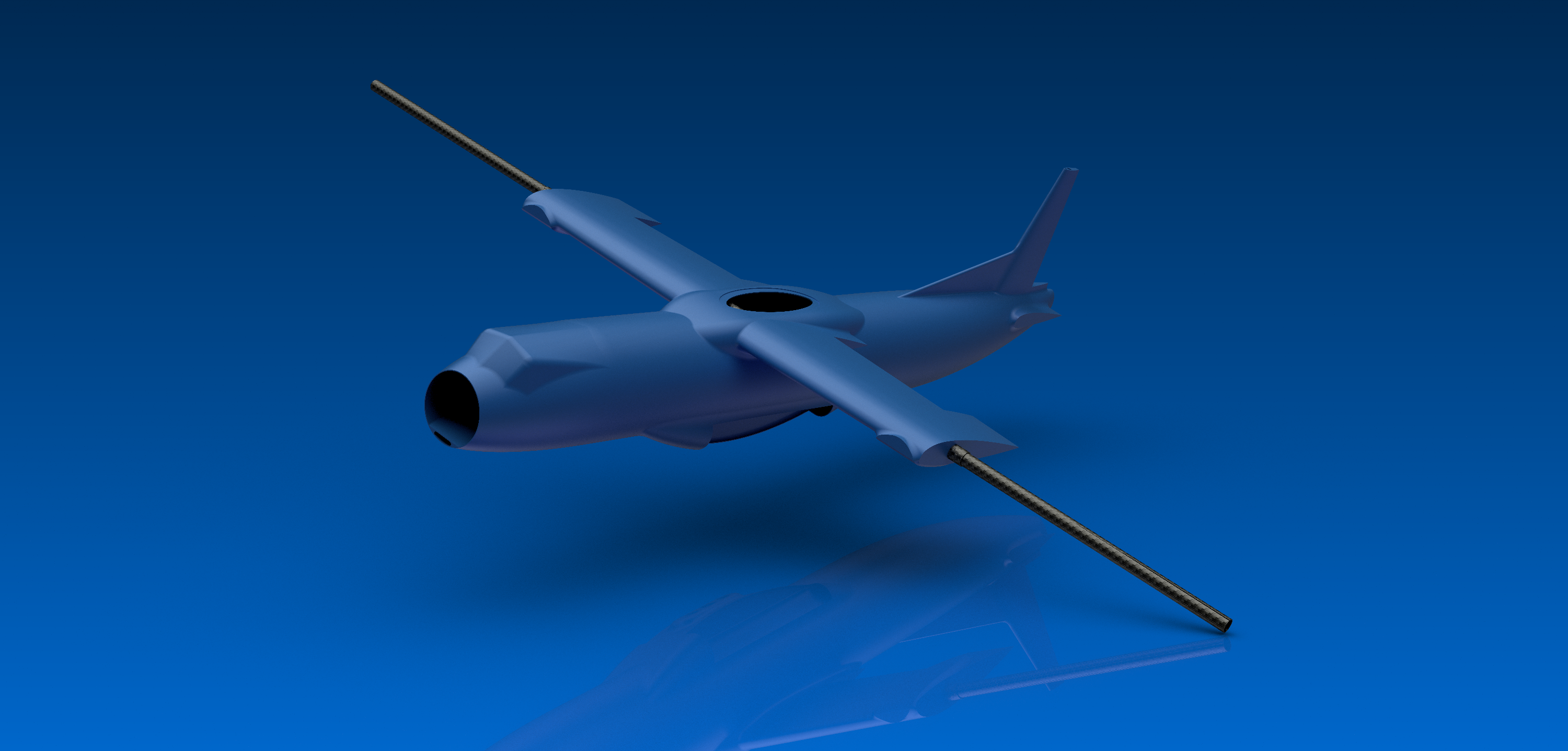

The under construction hollowed model

Anywho - I'm hoping that all this will give you guys reason and confidence to follow the progress of these open source models...I would love to hear any advice or suggestions you guys have; hopefully this thread will keep you all interested for a good while!

I've been a long time lurker on these forums, but I do a fair bit of designing/building/flying of planes, and it has been a long term goal for me to embark on a project specifically for by fixed wing fans and put it up on these forums and become a contributor myself. I've concocted the idea of a nice series of 3D printed planes, all of which would be open source, building up from a simple trainer all the way to long range FPV and aerobatics. This, I decided, will be the project (or series of) that gets posted to these forums. The first plane i'll be going for is the trainer; a simple easy to fly, easy to acquire, easy to repair entry level option for those who want to enter the hobby, but are daunted by the prices and complexity of some of the models out there.

The Trainer: OpenFlyer Mk. I:

Ideally, this plane would be no more than 1200 mm in span and 800 mm in length; my metric for cost of the frame is based off the cost of a 1 KG role of PETG filament: ~$40 (AU), $25 (US). My goal for the all up materials cost of printing this aircraft would be about half of the aforementioned numbers; this leaves the electronics as the main cost when building one of these planes...as is the usual.

Give those (remarkably basic) constraints, I've developed a very rudimentary sketch of an early model - surprise, it looks very familiar to many other tail daggers (for a reason)

Obviously this model is lacking in quite a few areas. This is just a 10 minute quick collection of my thoughts essentially; this aspect ratio, this chord, angle of incidence, span, sweep, and so on. The model will become much more refined, and will probably end up looking quite different to the one shown above, as it is changed to accommodate predicted loads or inadequacies in various areas of performance.

Desired (Nominal) Specifications:

Wingspan: 1100 mm

Length: 800 mm

Frame Weight: <500 Grams

Electronics Package Weight: <500 Grams

Static Thrust: >800 Grams

Top Speed: 30 m/s

Take Off Speed (clean b/c no flaps): 15 m/s

Cruise Speed: 25 m/s

Peak Engine Revolutions: 14000 RPM

Peak Engine Power: 170 Watts

Peak Engine Voltage: 12

Propeller: APC E 7x5

Flight Time: >30 Minutes

Max Cargo: >150 Grams

A Bit of Info About Me:

Seeing as I haven't contributed in the past, its probably fair I give a bit of background...show that I'm not just making wild guesses with all this

I'm a big fan of FliteTest's foam models, and the simple storch gave me a lot of good memories and experience; it also sent me down the endless path of designing building my own foam models, needless to say the first few didn't work out too great, but I got the hang of it eventually. I've always enjoyed using CAD software, and so it was inevitable that my interest in that would permeate through to my interest in planes...indeed it did! I started out designing a few wooden models that I had laser cut; by this point my experience with making practical designs and sourcing parts was decent enough that these wooden models were fairly reliable and fun to fly.

One of my favourite designs...a 2.5 meter behemoth

While designing these wooden models, I also started a few design projects that were only possible with 3D printing...they were fully fleshed out, servos, motors, control surfaces, all the goods, but they were shelved due to a lack of 3D printing capabilities. Recently though, I got a 3D printer...this has opened up quite a few of these projects again...its good to see them coming back to life

The concept model

The under construction hollowed model

Anywho - I'm hoping that all this will give you guys reason and confidence to follow the progress of these open source models...I would love to hear any advice or suggestions you guys have; hopefully this thread will keep you all interested for a good while!