Its time for version 2 of the scratch build ROV. The last design worked on land, but not in the water...which is unfortunate for a vehicle designed to work under water. Despite this fail with version 1, there was a lot that I learned about ROV design that I can apply to version 2. The main goals are the same; build an underwater vehicle capable of being controlled down to 50 feet of depth, with a camera feed to examine what's below.

Here are some of the major lessons I learned through the first version:

-Making watertight containers is difficult.

-The previous design had way too much buoyancy and the electronics I am using do not require a lot of room.

-If the thrust vector is not in line with the crafts CG, the ROV will not dive straight down or propel horizontally.

-Having a place to add ballast weight is important.

-Being able to adjust the thruster position is important.

-A spot to mount attachments such as an grabber arm in the future would be nice.

-It is best to keep the number of points of entry into the sealed compartment at a minimum

-It is probably more useful to have the lights and FPV camera pointed slightly downward than straight ahead.

-The electronics were hard to work on after installing in the body.

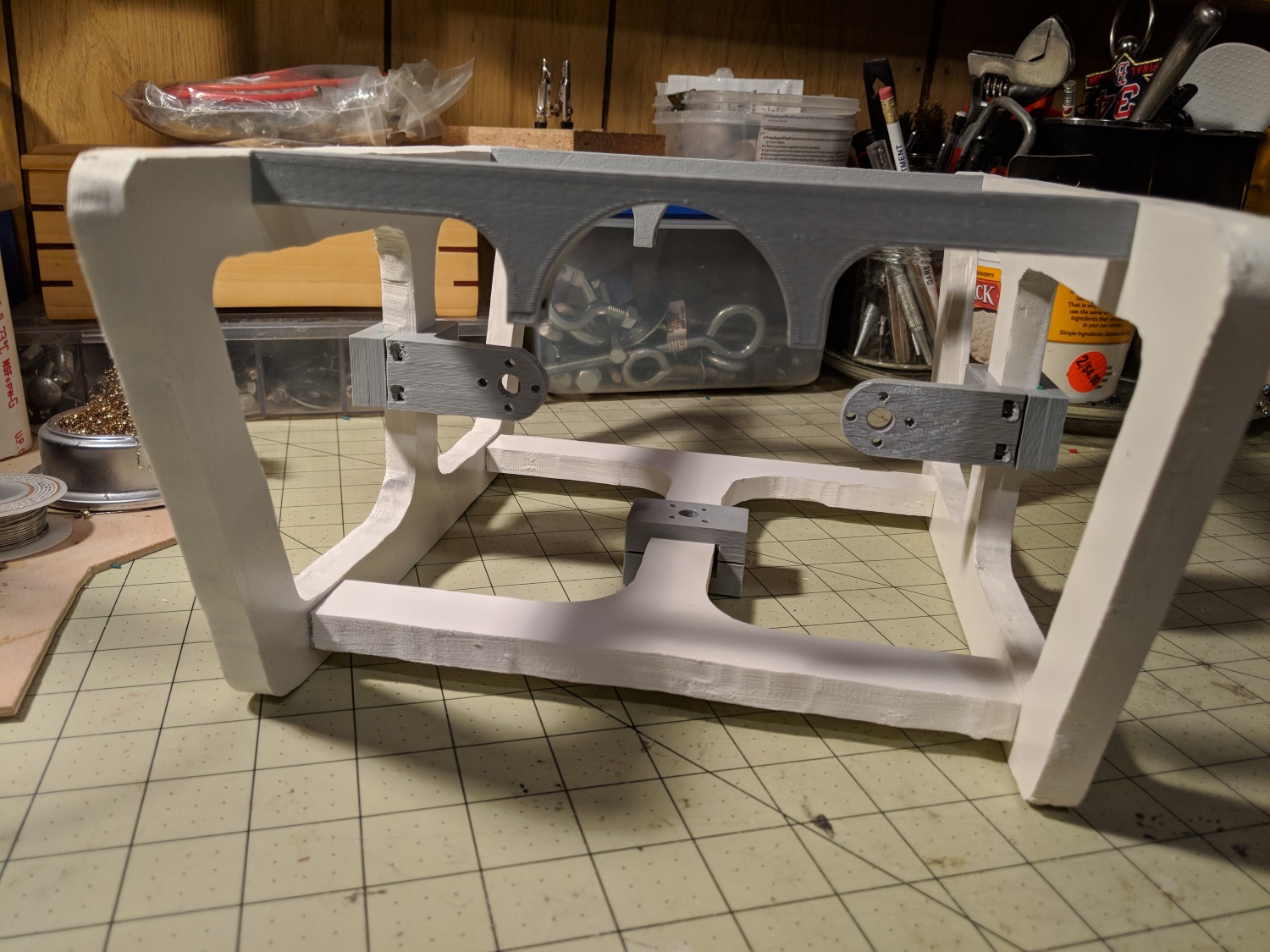

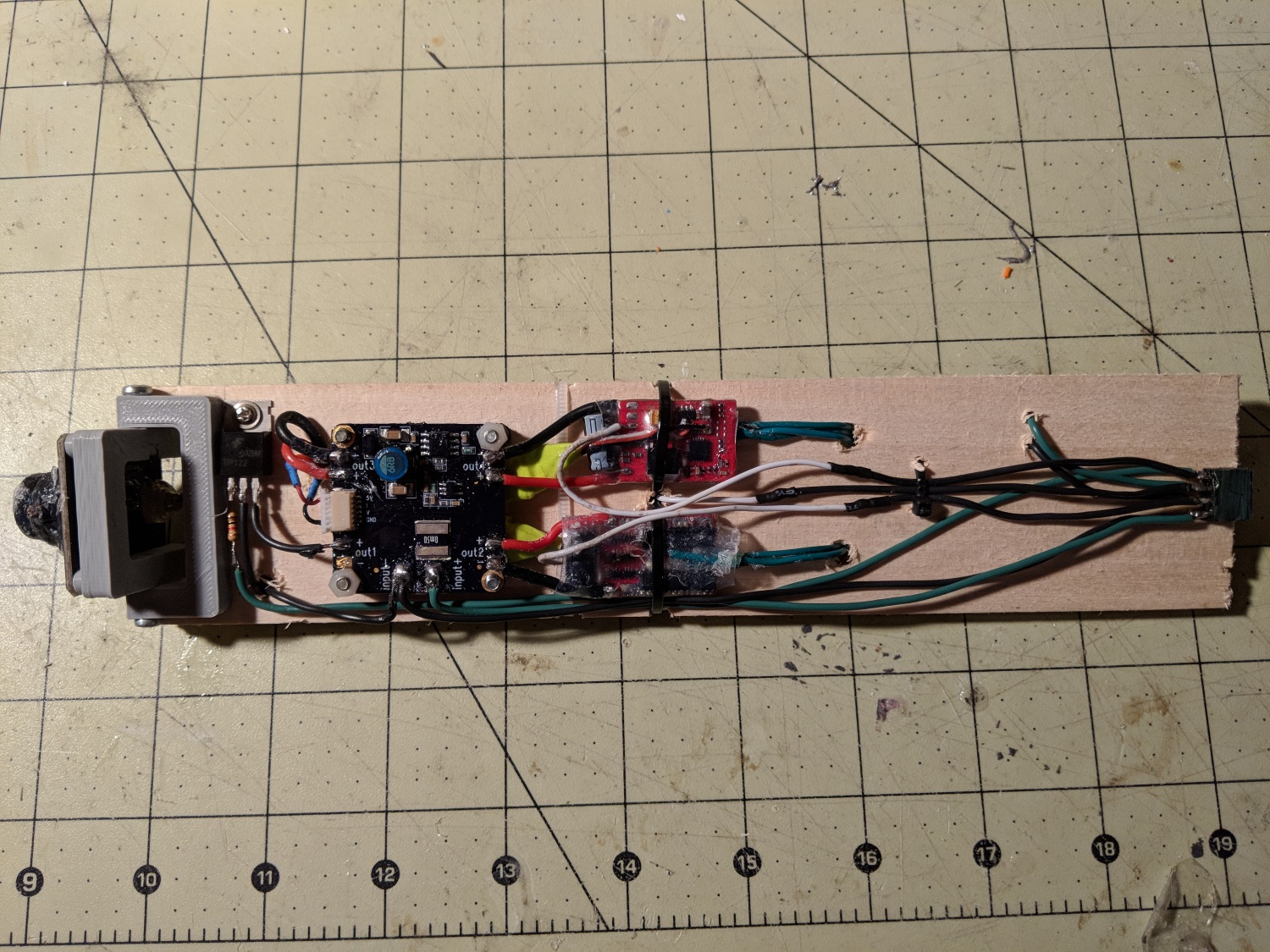

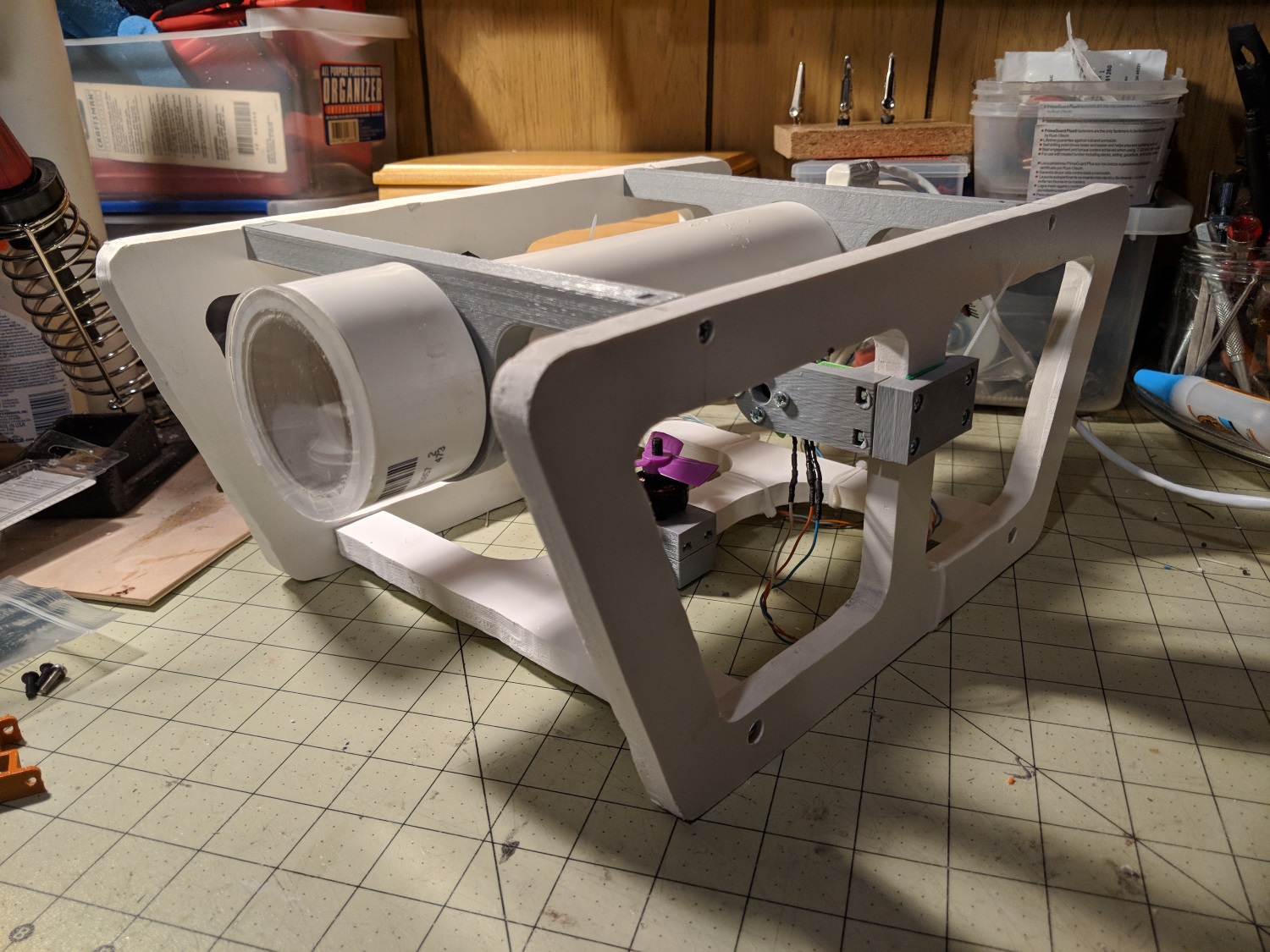

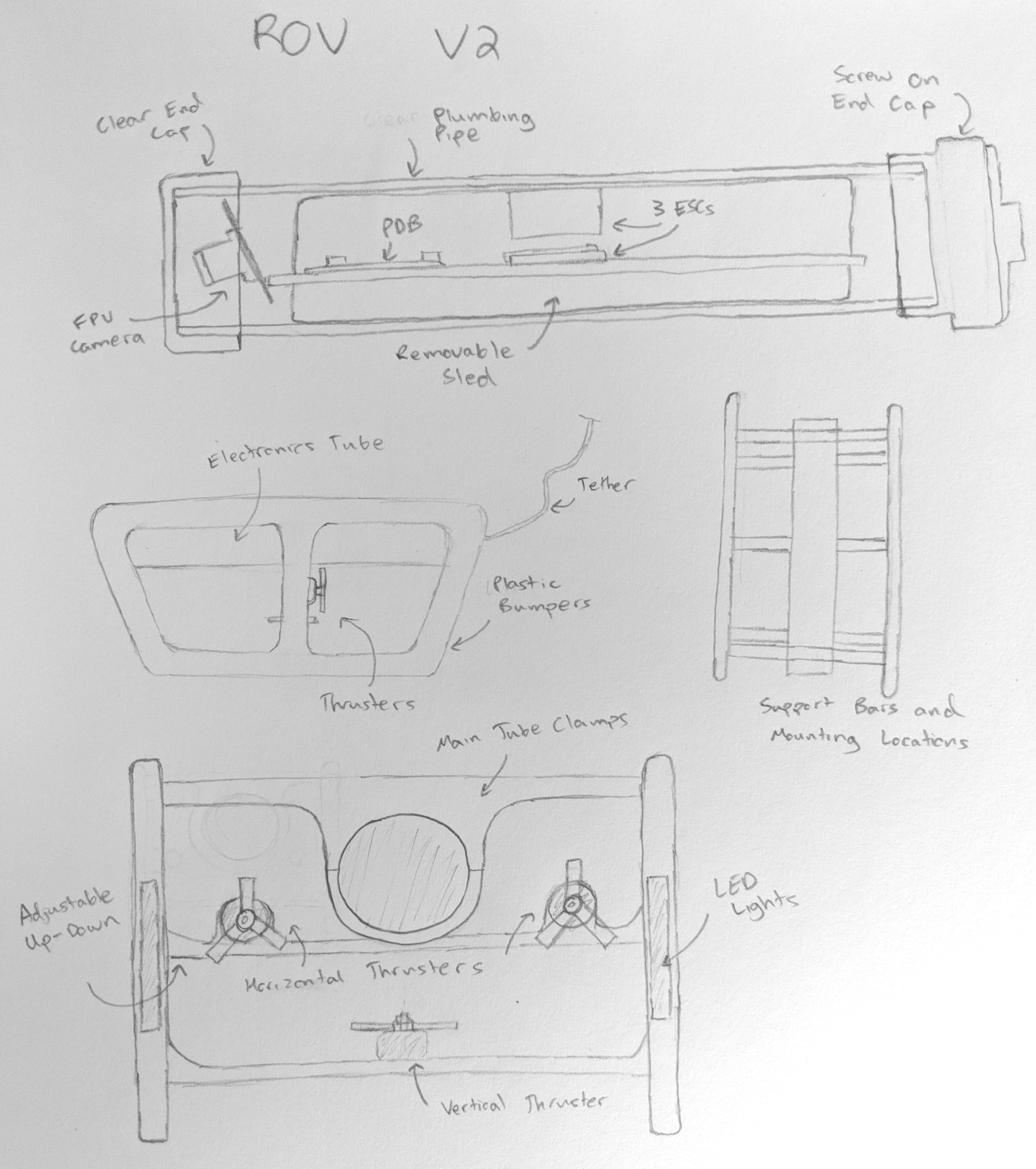

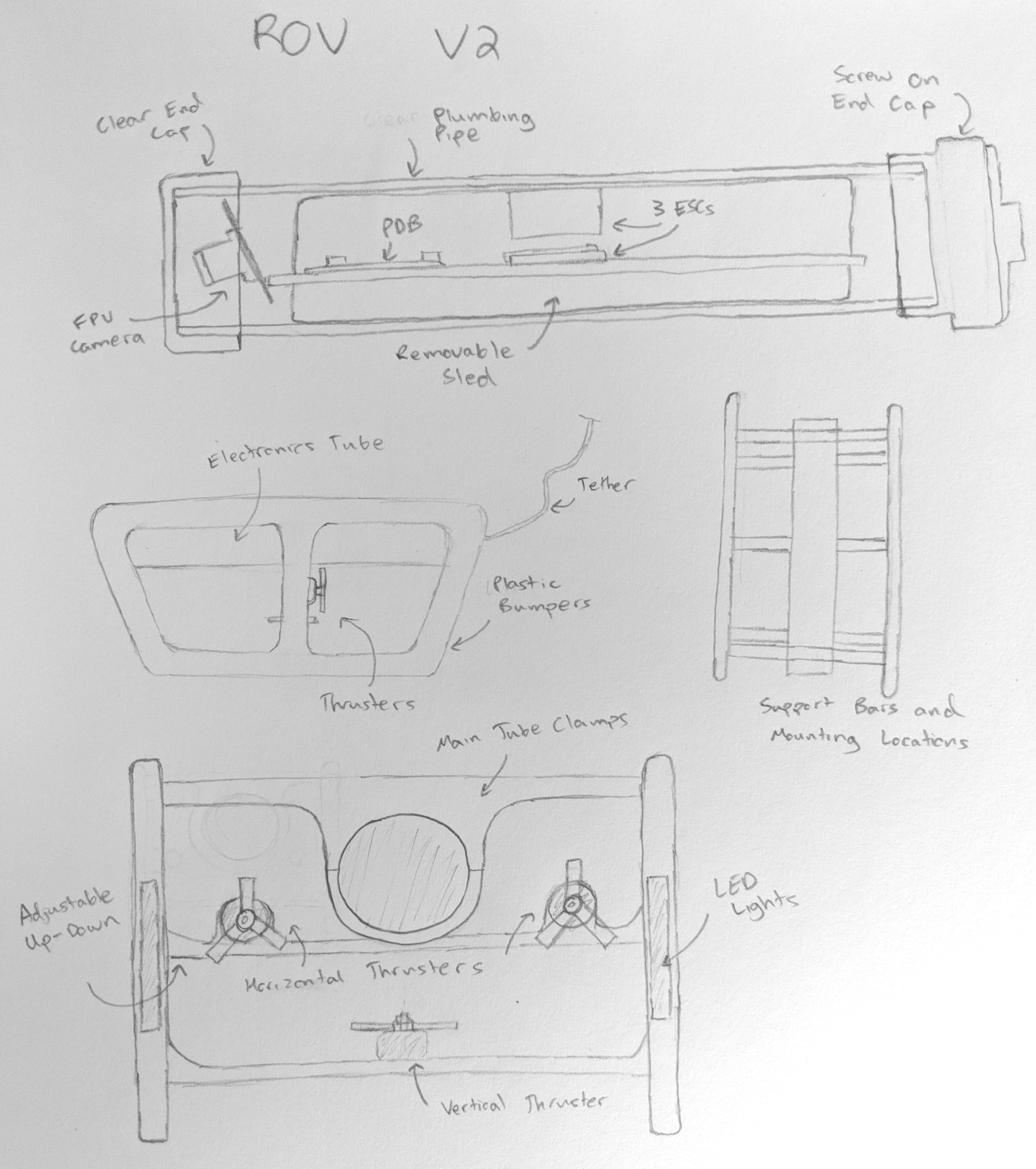

Based on these lessons, my plan for version 2 of the ROV is to start with getting a watertight container. The 3D printed body of the last design took a lot of time and work to build, and it was very difficult to make watertight. Instead of 3D printing a custom body, I plan on using a PVC pipe with one end permanently capped off, and the other with a removable cap. Hardware stores sell PVC pipes, caps, and removable ends that are designed to be watertight. It will also be much easier to assemble. Additionally, these PVC pipes are rated for certain pressures, so I will be able to tell if the construction will withstand the pressures at 50 ft of depth. I am also going for more of a traditional ROV design, with a smaller electronic container and a large exoskeleton of sorts, where equipment can be attached. The electronics will be mounted on a sled, which can be removed from the PVC tube for easy servicing. The position of the horizontal thrusters will also be adjustable vertically, to align the thrust vector with the CG.

CAD designs and renderings to come shortly!

Here are some of the major lessons I learned through the first version:

-Making watertight containers is difficult.

-The previous design had way too much buoyancy and the electronics I am using do not require a lot of room.

-If the thrust vector is not in line with the crafts CG, the ROV will not dive straight down or propel horizontally.

-Having a place to add ballast weight is important.

-Being able to adjust the thruster position is important.

-A spot to mount attachments such as an grabber arm in the future would be nice.

-It is best to keep the number of points of entry into the sealed compartment at a minimum

-It is probably more useful to have the lights and FPV camera pointed slightly downward than straight ahead.

-The electronics were hard to work on after installing in the body.

Based on these lessons, my plan for version 2 of the ROV is to start with getting a watertight container. The 3D printed body of the last design took a lot of time and work to build, and it was very difficult to make watertight. Instead of 3D printing a custom body, I plan on using a PVC pipe with one end permanently capped off, and the other with a removable cap. Hardware stores sell PVC pipes, caps, and removable ends that are designed to be watertight. It will also be much easier to assemble. Additionally, these PVC pipes are rated for certain pressures, so I will be able to tell if the construction will withstand the pressures at 50 ft of depth. I am also going for more of a traditional ROV design, with a smaller electronic container and a large exoskeleton of sorts, where equipment can be attached. The electronics will be mounted on a sled, which can be removed from the PVC tube for easy servicing. The position of the horizontal thrusters will also be adjustable vertically, to align the thrust vector with the CG.

CAD designs and renderings to come shortly!