Been looking at this build for over a year and finally decided to buy the parts and start working on it.

Link to website i am using with lots of good articles on everything: http://www.rckeith.co.uk/cnc-hot-wire-foam-cutter/

This is the same plans that Dave Foster (hazard wings) and Defiant wings are using to cut there wings that they sell.

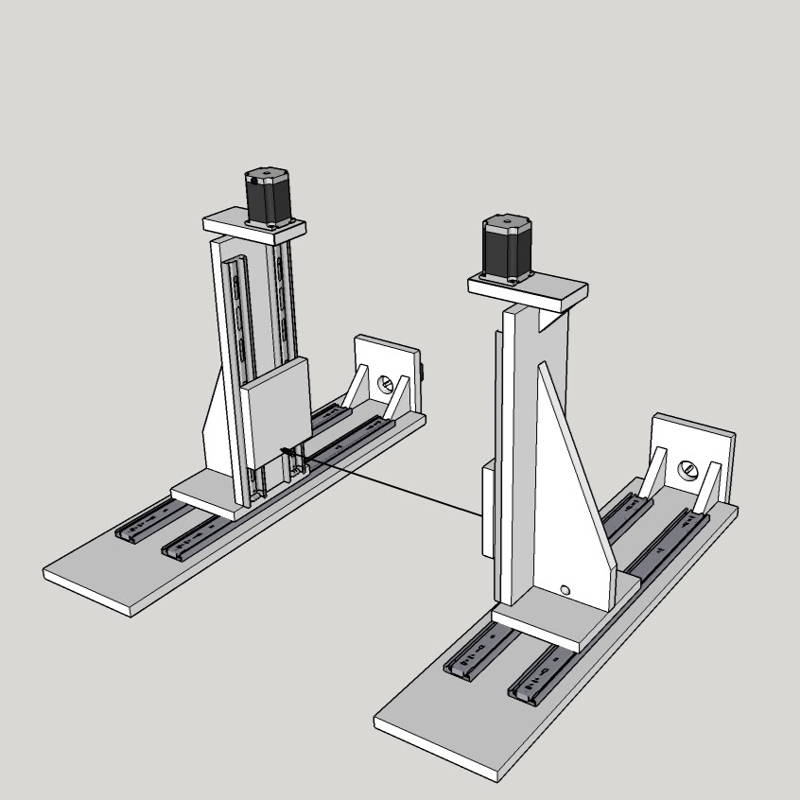

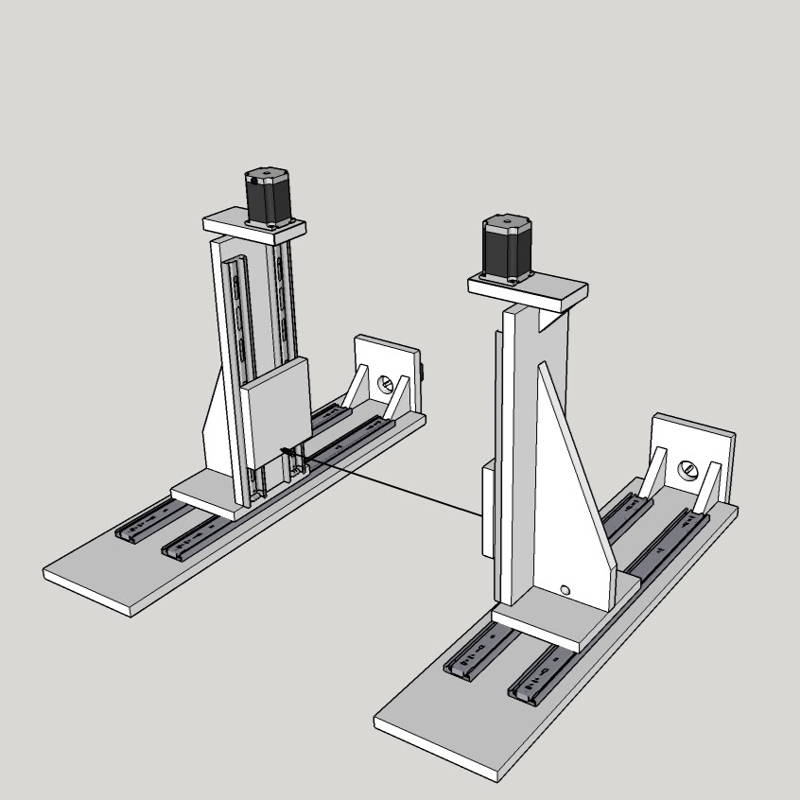

The construction is very basic. Some wood, in my case mdf, some drawer slides, 4 motors.

The one thing holding me back was that you needed to purchase CAM software, usually Mach3, which costs around $200. Recently keith has got LinuxCNC going which makes this free.

CAM software is what takes care of sending the gcode "code" to the motors. In 3d printing this is usually included for free or comes built into a control board on the machine. You need a computer or something always sending this data. There are other options, but the ones with the most tutorials and online info are for Mach3.

Another thing that made me finally go forward was i made some contacts with people that are using this stuff daily and actually respond to my question lol. So i have some confidence to move forward. I am starting this build log to document everything so i can do a full youtube tutorial later for anybody else. This way i can incrementally build up the info for later.

Estimated costs are around $300. You dont need the same precision for hot wire cutting foam as you do 3d printing or milling so you can get away from a lot more parts from Homedepot vs a cnc store. IE using steel acme rods instead of specific cnc lead screws etc.

Link to website i am using with lots of good articles on everything: http://www.rckeith.co.uk/cnc-hot-wire-foam-cutter/

This is the same plans that Dave Foster (hazard wings) and Defiant wings are using to cut there wings that they sell.

The construction is very basic. Some wood, in my case mdf, some drawer slides, 4 motors.

The one thing holding me back was that you needed to purchase CAM software, usually Mach3, which costs around $200. Recently keith has got LinuxCNC going which makes this free.

CAM software is what takes care of sending the gcode "code" to the motors. In 3d printing this is usually included for free or comes built into a control board on the machine. You need a computer or something always sending this data. There are other options, but the ones with the most tutorials and online info are for Mach3.

Another thing that made me finally go forward was i made some contacts with people that are using this stuff daily and actually respond to my question lol. So i have some confidence to move forward. I am starting this build log to document everything so i can do a full youtube tutorial later for anybody else. This way i can incrementally build up the info for later.

Estimated costs are around $300. You dont need the same precision for hot wire cutting foam as you do 3d printing or milling so you can get away from a lot more parts from Homedepot vs a cnc store. IE using steel acme rods instead of specific cnc lead screws etc.