clolsonus

Well-known member

I had a nugget of an idea tonight and was just wondering if something like this already exists. Background ... every time on a FT video they launch into some crazy new project, the say to start with some existing wing which is probably smart. But let's say I'm not one to follow advice, and I wanted something of a particular dimension (probably bigger than the average FT design) and wanted to figure out the sizes of things so it folded together right?

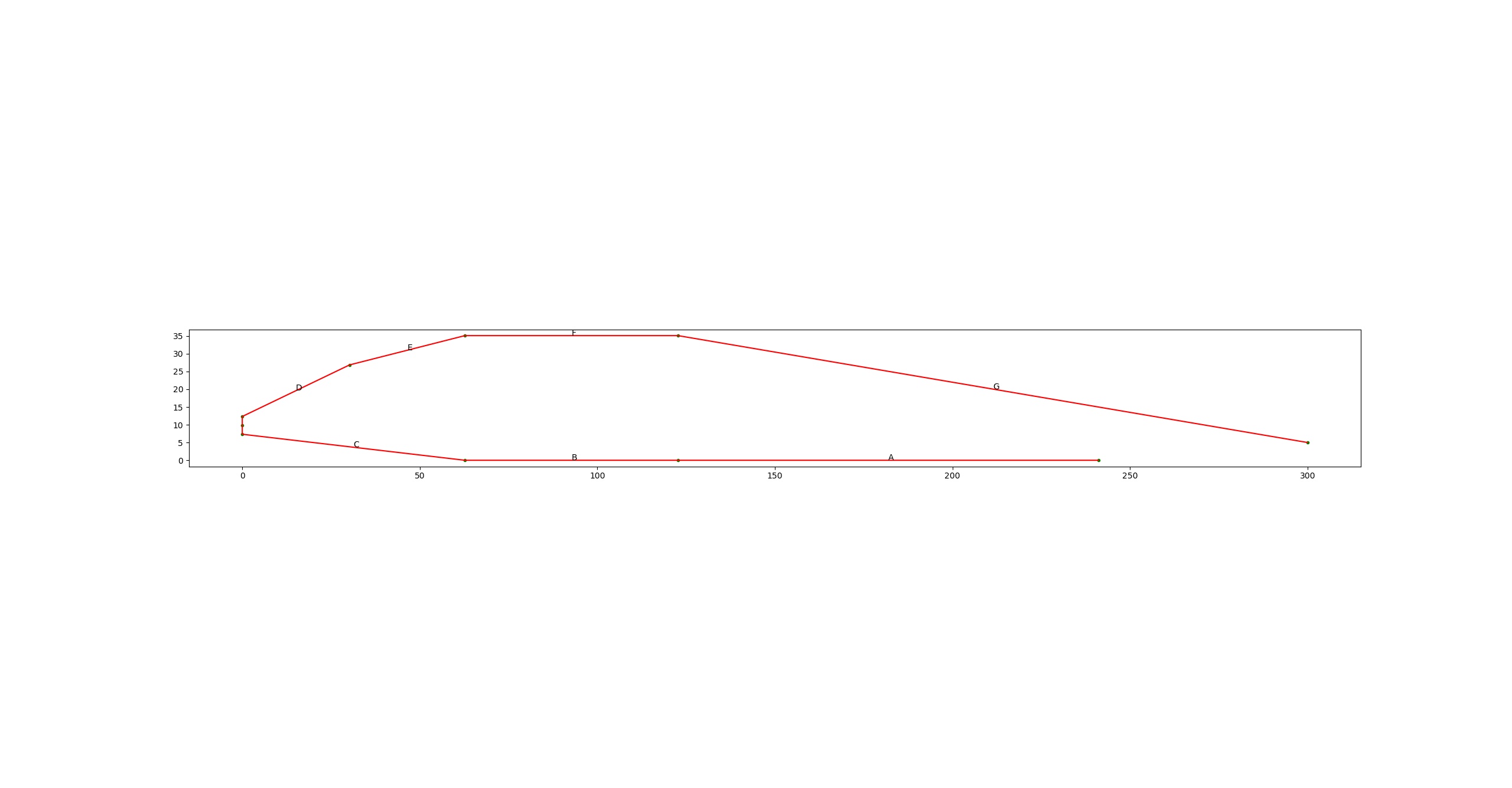

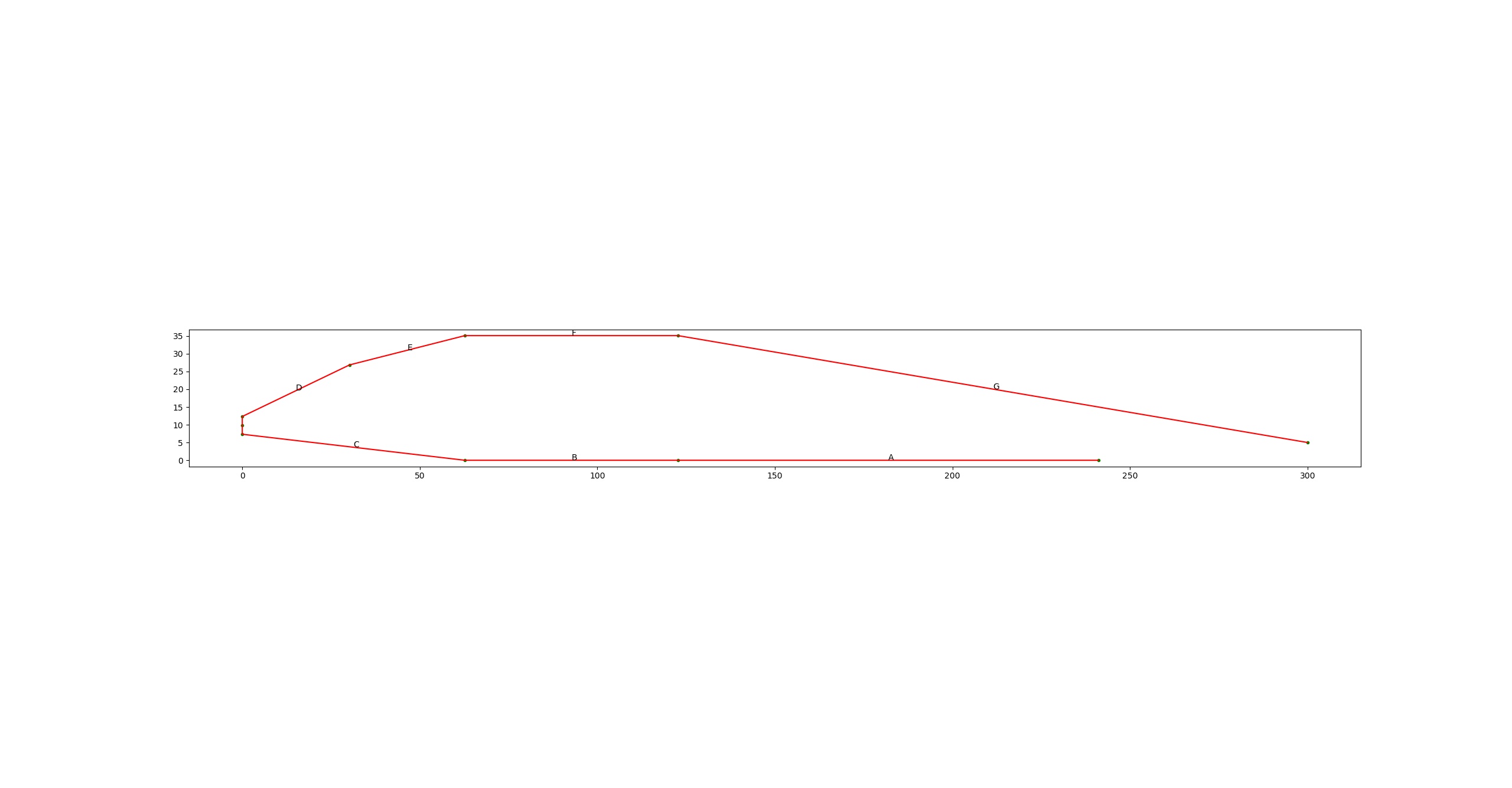

So I sat down and started puzzling through a python program where you would input the desired chord (let's say in mm) and it would spit out the dimensions you needed. It would kinda look like this (just a one evening hack, so very basic)

I could compute the lengths of the labeled edges (pad a little extra to make it around the leading edge radius) and would have enough to get out my ruler and start marking up a piece of foamboard. I could take it further and probably generate svg outlines given a wing span for the full cut file or at least a preview ...

Would this be stupid overkill? Is there something already far better? Is it just as easy to grab an existing wing design like FT recommends? Looking for thoughts/feedback if this would be useful or a waste of time? And I have plenty of other things to do so if it's a waste of time, be honest with me, I can take it!

Thanks!

Curt.

P.S. here's my quick hack python code.

So I sat down and started puzzling through a python program where you would input the desired chord (let's say in mm) and it would spit out the dimensions you needed. It would kinda look like this (just a one evening hack, so very basic)

I could compute the lengths of the labeled edges (pad a little extra to make it around the leading edge radius) and would have enough to get out my ruler and start marking up a piece of foamboard. I could take it further and probably generate svg outlines given a wing span for the full cut file or at least a preview ...

Would this be stupid overkill? Is there something already far better? Is it just as easy to grab an existing wing design like FT recommends? Looking for thoughts/feedback if this would be useful or a waste of time? And I have plenty of other things to do so if it's a waste of time, be honest with me, I can take it!

Thanks!

Curt.

P.S. here's my quick hack python code.

Code:

#!/usr/bin/env python3

# this is a quick test to compute dimensions for a flight test style

# folded foam board wing ... loosely based on the clarky airfoil sorta

# kinda

import math

import matplotlib.pyplot as plt

import numpy as np

# units: let's do mm

r2d = 180 / math.pi

material_mm = 5 # mm

# clarky numbers

max_thickness_perc = 0.117 # vertically proportional to chord

max_point_perc = .309 # longitudinally proportional to chord

le_raise_perc = .28 # vertically proportional to max height

# basic proportions

spar_perc = 0.20 # longitudinally proportional to chord

aileron_perc = 0.23 # desired overhang for ailerons

# edit this to size wing

chord_mm = 300

print("wing chord mm: %.0f" % chord_mm)

# compute things

max_mm = chord_mm * max_thickness_perc

print("max thickness mm: %.0f" % max_mm)

le_height_mm = max_mm * le_raise_perc

spar_width_mm = chord_mm * spar_perc

spar_height_mm = max_mm - 2*material_mm

print("spar width mm: %.0f" % spar_width_mm)

print("spar height mm: %.0f" % spar_height_mm)

max_point_mm = chord_mm * max_point_perc

half_spar = spar_width_mm * 0.5

spar_start_mm = max_point_mm - half_spar

spar_end_mm = max_point_mm + half_spar

print("spar start mm: %.0f" % spar_start_mm)

print("spar end mm: %.0f" % spar_end_mm)

le_crease_mm = spar_start_mm * 0.5

print("leading edge crease mm: %.0f" % le_crease_mm)

ail_overhang_mm = chord_mm * aileron_perc

print("desired aileron overhang mm: %.0f" % ail_overhang_mm)

# do trigs

aft_dist = chord_mm - spar_end_mm

print(aft_dist)

h = max_mm - material_mm

aft_hyp = math.sqrt( (h*h) + (aft_dist*aft_dist) )

print(aft_hyp)

angle = math.asin(h/aft_hyp)

print("angle deg:", angle*r2d)

mat2 = material_mm*2

act_overhang_mm = mat2 / math.tan(angle)

print("actual overhang: %.0f" % act_overhang_mm)

# inner points

nose = [material_mm, le_height_mm]

bot_front_spar = [spar_start_mm, material_mm]

bot_rear_spar = [spar_end_mm, material_mm]

top_front_spar = [spar_start_mm, max_mm-material_mm]

top_rear_spar = [spar_end_mm, max_mm-material_mm]

bot_te = [chord_mm-act_overhang_mm, material_mm]

final_te = [chord_mm, 0]

inner = np.array([bot_te,

bot_rear_spar,

bot_front_spar,

nose,

top_front_spar,

top_rear_spar,

final_te

])

# compute outer points

nose_bot = [0, le_height_mm - material_mm*0.5]

nose_true = [0, le_height_mm]

nose_top = [0, le_height_mm + material_mm*0.5]

bot_front_spar = [spar_start_mm, 0]

bot_rear_spar = [spar_end_mm, 0]

top_front_spar = [spar_start_mm, max_mm]

top_rear_spar = [spar_end_mm, max_mm]

bot_te = [chord_mm-act_overhang_mm, 0]

final_te = [chord_mm, material_mm]

# dance

xdiff = spar_start_mm

ydiff = max_mm - nose_top[1]

len = math.sqrt(xdiff*xdiff + ydiff*ydiff)

base = [nose_top[0] + xdiff*0.5, nose_top[1] + ydiff*0.5]

xoff = -ydiff*0.05

yoff = xdiff*0.05

crease = [base[0]+xoff, base[1]+yoff]

outer = np.array([bot_te,

bot_rear_spar,

bot_front_spar,

nose_bot,

nose_true,

nose_top,

crease,

top_front_spar,

top_rear_spar,

final_te

])

le_pad = (material_mm*2*math.pi)/4 - material_mm

print("leading edge radius pad: %.1f" % le_pad)

def my_annotate(ax, text, p1, p2):

p = (np.array(p1) + np.array(p2))*0.5

pt = p.copy()

#if side == "top":

# pt[1] += material_mm

#else:

# pt[1] -= material_mm

ax.annotate(text, xy=p, xytext=pt)

#arrowprops=dict(facecolor='black', shrink=0.05),

#horizontalalignment='right', verticalalignment='top')

# plot

fig = plt.figure()

ax = fig.add_subplot()

x, y = outer.T

ax.scatter( x, y, marker=".", color="g" )

ax.plot( x, y, color="r" )

#x, y = inner.T

#ax.scatter( x, y, marker=".", color="g" )

#ax.plot( x, y, color="b")

my_annotate(ax, "A", outer[0], outer[1])

my_annotate(ax, "B", outer[1], outer[2])

my_annotate(ax, "C", outer[2], outer[3])

my_annotate(ax, "D", outer[5], outer[6])

my_annotate(ax, "E", outer[6], outer[7])

my_annotate(ax, "F", outer[7], outer[8])

my_annotate(ax, "G", outer[8], outer[9])

ax.set_aspect('equal')

plt.show()